Pre-fabricated homes are useful for a number of reasons as they can offer versatile and unique dwellings in areas that are often difficult to access or not suitable for housing developments. The beauty of a pre-fab home is that they are quick to assemble in comparison to building a house and if the circumstances change they can be disassembled and moved to another location.

Roderick James architects LLP are an architectural company with other 30 years expeience in designing and creating unique builds in a wide variety of locations throughout the UK. These builds include houses, cabins, tree-houses and houseboats all designed with the mantra of creating a fun and informal space which avoids the sterotype of the square house with square rooms and square corners.

Recently they have launched a company called OUT of the BLUE Ltd to specialise in pre-fabricated modular living units that are suitable for isolated locations and extreme weather conditions. They approached MANiFAB with a concept for a new modular living unit and over two years the two companies have worked together to produce the Out of the Blue Airship.

The client Roderick James Architects LLP approached MANiFAB with a concept for the design and manufacture of a modular living unit. This was to be a contemporary, maintenance free, fully insulated flexible living space for Housing, Hideaways, Rooftops or Afloat.

The brief that MANiFAB were given included four specific design requirements.

The original concept was a design that incorporated a laminated timber frame with glazing at each end and clad with timber panels. However upon recieving the brief, the design team at MANiFAB suggested some structural changes to the architects at Roderick James as part of the initial discussions.

These proposed changes including building the frame out of aluminium rather than timber to make the structure lighter as well as using aluminium for the cladding panels to provide a weather tight skin. Once agreed with the client the design team at MANiFAB could take the next steps and begin to put together a design for the unit.

MANiFAB were well equipped to realise this design concept for the client thanks to their in-house design capabilities. Using the latest 3D CAD software removed the need for blank development so the design could go stright through into production ensuring that the process was quick and cost effective. As well as that the ability to carry out pre-manufacture strength and structure analysis meant that the client was protected against costly misjudgements.

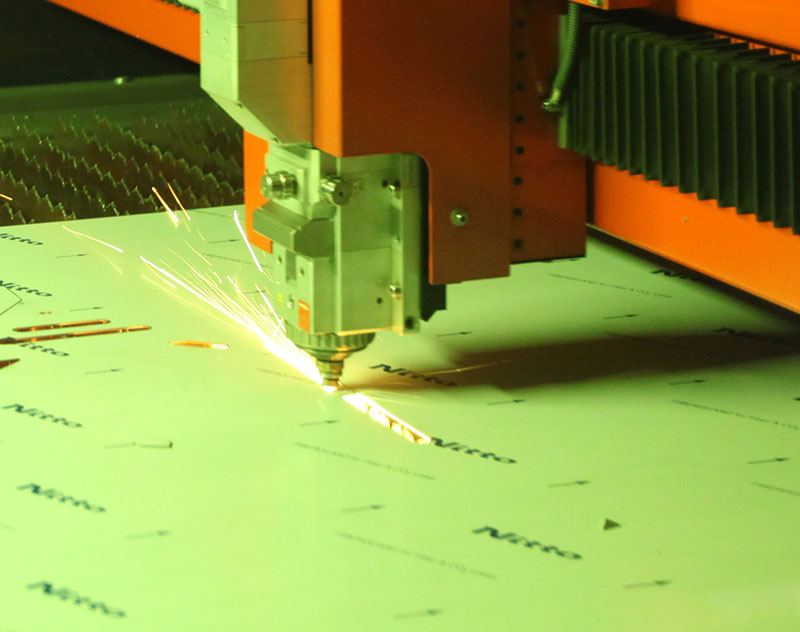

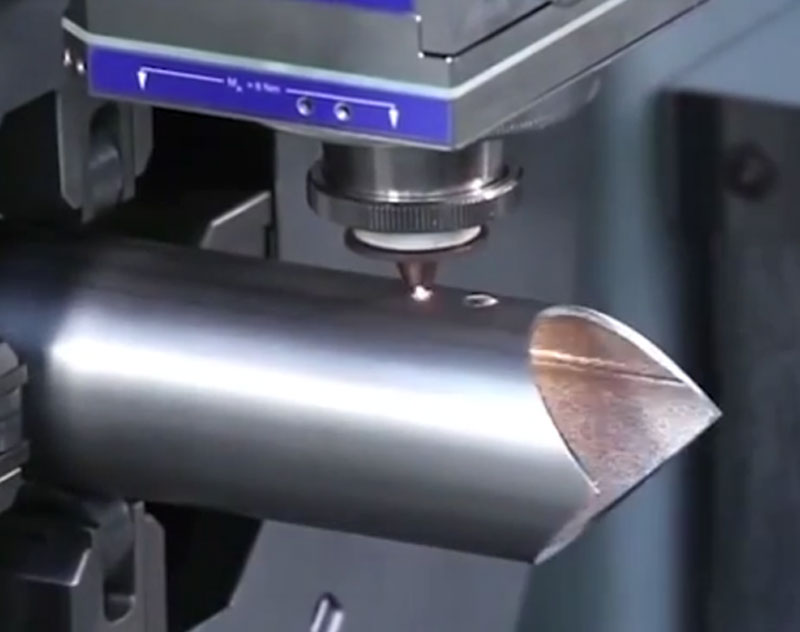

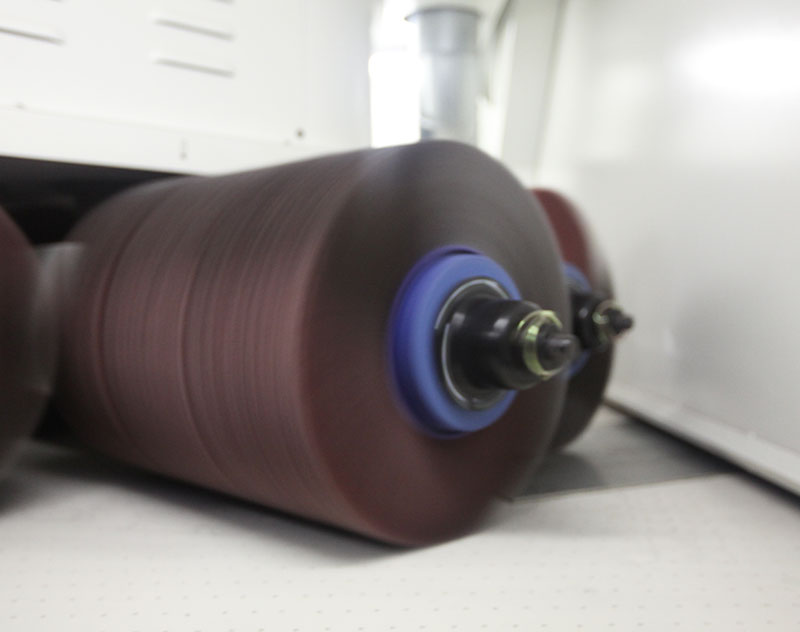

A highly skilled production team coupled with the latest in manufacturing technologies ensured that the finished product was of the highest quality and completely repeatable with precision for future commissions.

To ensure that every aspect of the project fits the brief, MANiFAB strive to work in complete collaboration with the client involving regular contact points, progress checks and prototyping work. The following is a breakdown of how the team at MANiFAB work to carry out bespoke projects such as this one.

Following on from the completion of the project consultation and feedback sessions were held with the client to assess the success of the project overall and provide any revisions or changes that could be made.

On the whole the client was pleased with how the project was carried out. The main change to the design that was suggested was that the orientation of the cladding should be changed from vertical to horizontal.

Thanks to the success of this initial project a second prototype has been produced and is currently being installed in south east England and a further two units have been manufactured and will be despatched soon at locations to be agreed.

The following Manufacturing processes were used throughout the construction of this project.

Our 11,500-square-metre facility is always open to our clients, and we encourage you to come and visit. Appointments can be made by phone or email and we will happily provide a full tour for you to see just what MANiFAB is capable of.